Duke's'72 Carbed KA project

Re: Duke's'72 Carbed KA project

Thanks for all the input guys. The gears are turning. Would any of you happen to know the length of the lever arm on your sway bar? I am really trying to avoid running the bar underneath the control arm. My current plan is to make a 1.125 solid bar that follows the same path as my current bar. I also had thoughts of running a stock car style splined hollow bar with aluminum arms, but the arms would have to be pretty long and I would have to run a HUGE bar to achieve my desired roll rate.

On the topic of ride height and roll center, I am going to look into that as well. I have raised the LCA and T/C rod pivots and I run 1" RCA's so the geometry isn't horrible. It would be interesting though to plot it all out to find out what the geometry really looks like.

On the topic of ride height and roll center, I am going to look into that as well. I have raised the LCA and T/C rod pivots and I run 1" RCA's so the geometry isn't horrible. It would be interesting though to plot it all out to find out what the geometry really looks like.

Duke Schimmer

'72 2-Door 510

"Simplify and add lightness."

'72 2-Door 510

"Simplify and add lightness."

- bertvorgon

- Supporter

- Posts: 12017

- Joined: 04 Aug 2003 20:45

- Location: White Rock, B.C. Canada

Re: Duke's'72 Carbed KA project

I will measure mine at lunch for you, car is on jack stands at the moment so it is easy to do. Stay tuned!

"Racing makes heroin addiction look like a vague wish for something salty" - Peter Egan

Keith Law

1973 2 Door Slalom/hill climb/road race / canyon carver /Giant Killer 510

1971 Vintage 13' BOLER trailer

Keith Law

1973 2 Door Slalom/hill climb/road race / canyon carver /Giant Killer 510

1971 Vintage 13' BOLER trailer

- bertvorgon

- Supporter

- Posts: 12017

- Joined: 04 Aug 2003 20:45

- Location: White Rock, B.C. Canada

Re: Duke's'72 Carbed KA project

From the inside curve of the bar, CENTER of the bend, to the mounting bolt point at the rod end, I measured 7.5".

You can see the slight kink we put into the bar too. We spent a whole night bending this thing, using a rosebud tip, it took both Andy and I to bend it. The bar was almost virtually white hot looking, I never sweat so much in my life as working on that. We had the pillow blocks made, then just kept test fitting till the bar was square on both sides. Any slight discrepancy was taken care of by the threaded rod going up into the control arm. I just use the good poly bushings up top, tightened down really good. That way there is some shock load relief.

Hope that helps.

You can see the slight kink we put into the bar too. We spent a whole night bending this thing, using a rosebud tip, it took both Andy and I to bend it. The bar was almost virtually white hot looking, I never sweat so much in my life as working on that. We had the pillow blocks made, then just kept test fitting till the bar was square on both sides. Any slight discrepancy was taken care of by the threaded rod going up into the control arm. I just use the good poly bushings up top, tightened down really good. That way there is some shock load relief.

Hope that helps.

- Attachments

-

- IMGP7532 (Large).JPG (324.06 KiB) Viewed 4158 times

-

- IMGP7530 (Large).JPG (362.79 KiB) Viewed 4158 times

"Racing makes heroin addiction look like a vague wish for something salty" - Peter Egan

Keith Law

1973 2 Door Slalom/hill climb/road race / canyon carver /Giant Killer 510

1971 Vintage 13' BOLER trailer

Keith Law

1973 2 Door Slalom/hill climb/road race / canyon carver /Giant Killer 510

1971 Vintage 13' BOLER trailer

Re: Duke's'72 Carbed KA project

That helps a bunch. Thanks Keith. It gives me a good idea of what I am shooting for with regards to roll stiffness.

I had another idea brought to me by a friend. The suggestion to mount the sway bar directly to the strut tube. There is some discussion over on Sleepys-14 build thread (starting around the middle of the page here http://www.the510realm.com/viewtopic.ph ... &start=120). This would put me in the right ballpark for roll stiffness and I wouldn't have to make a new anti-roll bar, but it seems like there are some downsides. I might start another thread to discuss this as I'm having trouble picturing how the force of the sway bar will affect steering as S15DET was saying.

I had another idea brought to me by a friend. The suggestion to mount the sway bar directly to the strut tube. There is some discussion over on Sleepys-14 build thread (starting around the middle of the page here http://www.the510realm.com/viewtopic.ph ... &start=120). This would put me in the right ballpark for roll stiffness and I wouldn't have to make a new anti-roll bar, but it seems like there are some downsides. I might start another thread to discuss this as I'm having trouble picturing how the force of the sway bar will affect steering as S15DET was saying.

Duke Schimmer

'72 2-Door 510

"Simplify and add lightness."

'72 2-Door 510

"Simplify and add lightness."

-

Uber Deaf One

- Posts: 131

- Joined: 01 Jan 2011 13:57

- Location: Santa Clara, CA

Re: Duke's'72 Carbed KA project

The extra weight of the iron block KA may be causing more roll as well... but you're already at 350 lb springs, so idk.

Got to love that transition from street tires to stickies... think I'll hold off on that for a while ha.

Got to love that transition from street tires to stickies... think I'll hold off on that for a while ha.

Re: Duke's'72 Carbed KA project

Seriously! I have been driving the car on the street for the past few days with my BFG Rivals and it is crazy how much different it feels.Uber Deaf One wrote:The extra weight of the iron block KA may be causing more roll as well... but you're already at 350 lb springs, so idk.

Got to love that transition from street tires to stickies... think I'll hold off on that for a while ha.

The extra weight of the KA was precisely the reason for running the 350# springs.

Duke Schimmer

'72 2-Door 510

"Simplify and add lightness."

'72 2-Door 510

"Simplify and add lightness."

- bertvorgon

- Supporter

- Posts: 12017

- Joined: 04 Aug 2003 20:45

- Location: White Rock, B.C. Canada

Re: Duke's'72 Carbed KA project

I forgot you had that bit of extra weight, hence the 350's.

Tires make such a difference, always have, always will. When you consider my car was set up for the stickiest race slicks at the time, it tells you something that I have not changed anything with my street DOT race tires now. While I may have more "final" grip due to the amount of rubber on the road with 9.5" slicks, the radial component gives me better "feel' when it get to their limit.

I have no experience with a bar to the strut, so can't comment on that.

Tires make such a difference, always have, always will. When you consider my car was set up for the stickiest race slicks at the time, it tells you something that I have not changed anything with my street DOT race tires now. While I may have more "final" grip due to the amount of rubber on the road with 9.5" slicks, the radial component gives me better "feel' when it get to their limit.

I have no experience with a bar to the strut, so can't comment on that.

"Racing makes heroin addiction look like a vague wish for something salty" - Peter Egan

Keith Law

1973 2 Door Slalom/hill climb/road race / canyon carver /Giant Killer 510

1971 Vintage 13' BOLER trailer

Keith Law

1973 2 Door Slalom/hill climb/road race / canyon carver /Giant Killer 510

1971 Vintage 13' BOLER trailer

-

Uber Deaf One

- Posts: 131

- Joined: 01 Jan 2011 13:57

- Location: Santa Clara, CA

Re: Duke's'72 Carbed KA project

The only issue I see with a bigger front bar is it may pick up the inside front tire, and probably won't fix the inside rear coming off the ground issue. Maybe try 375-400 lb springs, see what happens?

I'm currently at 275 lb up front with my KA 510 and IMO that's too soft. My 300 tread wear tires have ridiculously soft sidewalls, once I get real street tires I will prob have to go a little stiffer. Do you know what your weight distribution is?

I'm currently at 275 lb up front with my KA 510 and IMO that's too soft. My 300 tread wear tires have ridiculously soft sidewalls, once I get real street tires I will prob have to go a little stiffer. Do you know what your weight distribution is?

- Dave Patten

- Supporter

- Posts: 838

- Joined: 20 Jun 2008 13:30

- Location: Dunbarton, NH

Re: Duke's'72 Carbed KA project

Duke,

Here is an idea on increasing the front bar rate with out changing it. Attach the sway bar link to the strut rather than the LCA.

This will act like a bigger diameter because the bar end sees full wheel motion as opposed to partial wheel movement by being linked to the LCA inboard of the strut.

Just an idea.

Here is an idea on increasing the front bar rate with out changing it. Attach the sway bar link to the strut rather than the LCA.

This will act like a bigger diameter because the bar end sees full wheel motion as opposed to partial wheel movement by being linked to the LCA inboard of the strut.

Just an idea.

-

Sleepys-14

- Posts: 434

- Joined: 03 Mar 2011 11:26

- Location: Appleton, WI

Re: Duke's'72 Carbed KA project

My car weighs 2100lbs full without driver, with a 52/48 distribution. I run BFG rivals, and I would not run less than 300lb springs even with a 1.125" front bar. With even stickier tires, she is really going to be leanin! At a few tracks around here, I use the full stroke of the suspension in some of the compression corners. 300lb is as low as I would go for any track, and stiffer for some of the more demanding ones.

Here is my car at full lean at an auto-x (~30mph)

This is the carousel at Road America (~80mph)

This is Brainard (~60mph)

Im not saying my car is perfect, because it is far from, but I think I have found a ballance between spring rates and swaybars. Yours looks looks like it is leaning a little too much considering your spring rates. It would be nice to see if the weight distribution is somewhere in the ballpark of ~55/45 or less.

Here is my car at full lean at an auto-x (~30mph)

This is the carousel at Road America (~80mph)

This is Brainard (~60mph)

Im not saying my car is perfect, because it is far from, but I think I have found a ballance between spring rates and swaybars. Yours looks looks like it is leaning a little too much considering your spring rates. It would be nice to see if the weight distribution is somewhere in the ballpark of ~55/45 or less.

Beer... The cause of, and solution to, all of lives problems- Homer Simpson

Re: Duke's'72 Carbed KA project

Sleepy, I used Rivals most of last year and I have been using them as street tires for the past few months. For those tires, I feel like the setup is awesome. I can pretty much make the car do whatever I want. The handling is very neutral, and body roll is minimal. However, the added grip of the R-compound tires changed things quite a bit. After having a few people tell me that the difference in grip between these two tires wouldn't be that huge, I was pretty confident that the setup would basically carry over. This obviously was not the case.

From an earlier post:Dave Patten wrote:Duke,

Here is an idea on increasing the front bar rate with out changing it. Attach the sway bar link to the strut rather than the LCA.

This will act like a bigger diameter because the bar end sees full wheel motion as opposed to partial wheel movement by being linked to the LCA inboard of the strut.

Just an idea.

The friend actually forwarded me a message that you posted on the BBList. I have come up with a way to do this that I think should work pretty well, and requires fairly little fabrication. I'm going to tackle this next week and hopefully have it done for the next event on 3/29.duke wrote: I had another idea brought to me by a friend. The suggestion to mount the sway bar directly to the strut tube. There is some discussion over on Sleepys-14 build thread (starting around the middle of the page here http://www.the510realm.com/viewtopic.ph ... &start=120). This would put me in the right ballpark for roll stiffness and I wouldn't have to make a new anti-roll bar, but it seems like there are some downsides. I might start another thread to discuss this as I'm having trouble picturing how the force of the sway bar will affect steering as S15DET was saying.

Duke Schimmer

'72 2-Door 510

"Simplify and add lightness."

'72 2-Door 510

"Simplify and add lightness."

Re: Duke's'72 Carbed KA project

That's an interesting solution and fairly strait forward.

I can easily envision a clamp mount to the strut with a boss for a link extending downward to the stock sway bar location. And since its between the strut and the inner fender, clearance shouldn't be too much of an issue.

Keep us posted Duke.

Byron

I can easily envision a clamp mount to the strut with a boss for a link extending downward to the stock sway bar location. And since its between the strut and the inner fender, clearance shouldn't be too much of an issue.

Keep us posted Duke.

Byron

Love people and use things,

because the opposite never works.

because the opposite never works.

- Dave Patten

- Supporter

- Posts: 838

- Joined: 20 Jun 2008 13:30

- Location: Dunbarton, NH

Re: Duke's'72 Carbed KA project

Here is a clamp on boss with 1/2" thread designed for a 2"tube.

UB Machine P/N 35-3328

UB Machine P/N 35-3328

- StrutlessWonder

- Supporter

- Posts: 334

- Joined: 03 Mar 2012 12:59

- Location: Menlo Park, CA

Re: Duke's'72 Carbed KA project

Another option: Custom Speedway tubular bar, which would allow for bar-swapping or end-swapping tuneability.

My Strutless car is a 2600lb pig (fully loaded w/ me in the driver's seat) on 205/40-17 Nitto NT-01 R-compounds, 310# wheel rate at all 4 corners, and 335lb RW Tq.

I have front double A-arms and inboard coil-overs w/ a custom 350lb Speedway tubular frt bar:

Speedway Engineering hollow 1 ¼” diameter 48-spline 1.25”x32”x.120 wall thickness with custom bent #613-3 steel arms, heim-jointed ends, and DGR Fabrication mounting plates

I also run a 3/4" rear bar, Sti R180 cLSD, TeamThump Penultimate, heim-jointed rear 280ZX control arms, 280ZX rear coil-overs, etc. I still haven't dialed in the rear setup, and I may have spring stacking issues, requiring longer springs.

Bending these super-beefy (heavy) end-plates is a pain.

Notch w/ a chopsaw and bend in 20-ton press, then weld the notch closed.

Or cut them short and bend up a cool tubular end (easier to bend) to weld in place (kind of like a flat drop-out is welded into in a tubular bicycle fork) and attach to control arm or strut.

Crappy pictures of blank and bent up bar ends in place:

My Strutless car is a 2600lb pig (fully loaded w/ me in the driver's seat) on 205/40-17 Nitto NT-01 R-compounds, 310# wheel rate at all 4 corners, and 335lb RW Tq.

I have front double A-arms and inboard coil-overs w/ a custom 350lb Speedway tubular frt bar:

Speedway Engineering hollow 1 ¼” diameter 48-spline 1.25”x32”x.120 wall thickness with custom bent #613-3 steel arms, heim-jointed ends, and DGR Fabrication mounting plates

I also run a 3/4" rear bar, Sti R180 cLSD, TeamThump Penultimate, heim-jointed rear 280ZX control arms, 280ZX rear coil-overs, etc. I still haven't dialed in the rear setup, and I may have spring stacking issues, requiring longer springs.

Bending these super-beefy (heavy) end-plates is a pain.

Notch w/ a chopsaw and bend in 20-ton press, then weld the notch closed.

Or cut them short and bend up a cool tubular end (easier to bend) to weld in place (kind of like a flat drop-out is welded into in a tubular bicycle fork) and attach to control arm or strut.

Crappy pictures of blank and bent up bar ends in place:

- Attachments

-

- swaybarblank.JPG (49.41 KiB) Viewed 3905 times

-

- swaybar1.jpg (48.4 KiB) Viewed 3905 times

Kurt Hafer

'70 2dr VG30et "Strutless Wonder"

'70 2dr VG30et "Strutless Wonder"

Re: Duke's'72 Carbed KA project

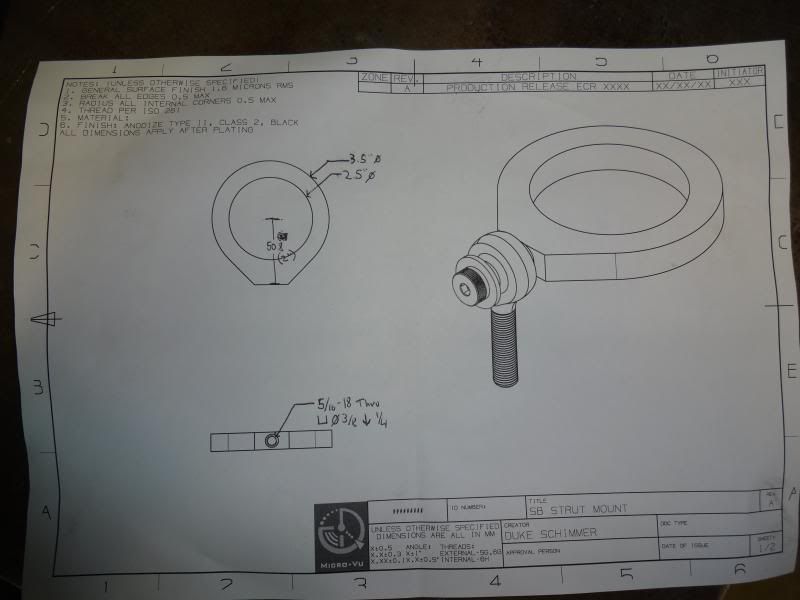

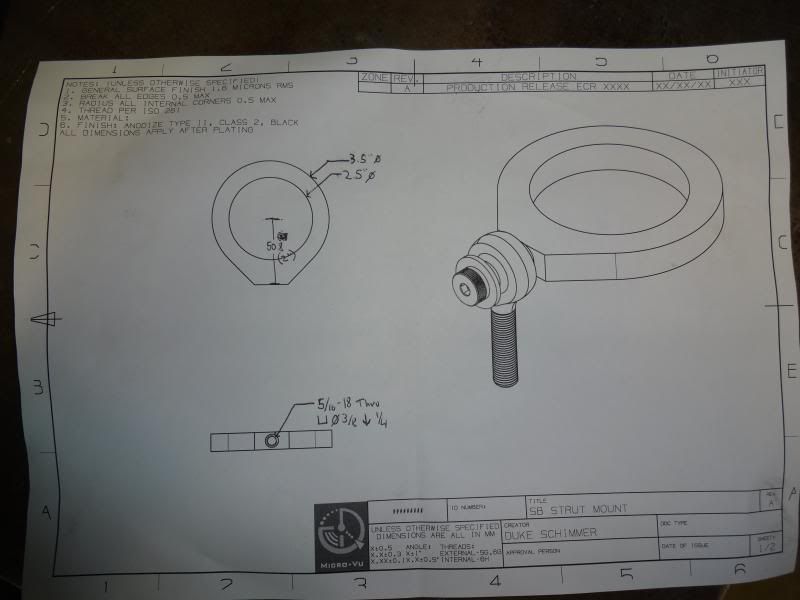

I have been working on modifying the sway bar mounting points for the last week or so. As a recap, I am moving the mounting points for the front sway bar from the control arms to the strut tube to effectively increase the stiffness of the bar without having to make a new one. After a little thought and bouncing of ideas between my dad and I, we came up with a mount that would enable me to run the longest links possible, would be easy to make, and would be easy to remove if it didn't work out as planned. I modeled up a concept in CAD and this is what I came up with.

It clamps to a 2.5" coilover spring adjuster nut which is then threaded onto the coilover sleeve below the nut which supports the spring. This nut is then jammed against the nut supporting the spring, securing the sway bar mount between the two. The link mounts to this with a 3/8" shoulder bolt which threads into a counter bored hole so that the shoulder of the bolt, not the threaded portion, is taking the load of the sway bar. A little time on the mill and this concept was brought to reality.

With this setup I was able to use very long end links which helps with the sway bar geometry and helps reduce the influence that the sway bar would have on steering.

First drive impressions are very positive. Front roll stiffness is noticeably increased and the influence of the sway bar force on steering is not minimal (I'm sure there may be some, but I can't feel it while driving). The real test will come this Saturday at the next auto-x event where I'm hoping that the extra roll stiffness will help keep the body roll I was experiencing after switching to R-compound tires under control.

It clamps to a 2.5" coilover spring adjuster nut which is then threaded onto the coilover sleeve below the nut which supports the spring. This nut is then jammed against the nut supporting the spring, securing the sway bar mount between the two. The link mounts to this with a 3/8" shoulder bolt which threads into a counter bored hole so that the shoulder of the bolt, not the threaded portion, is taking the load of the sway bar. A little time on the mill and this concept was brought to reality.

With this setup I was able to use very long end links which helps with the sway bar geometry and helps reduce the influence that the sway bar would have on steering.

First drive impressions are very positive. Front roll stiffness is noticeably increased and the influence of the sway bar force on steering is not minimal (I'm sure there may be some, but I can't feel it while driving). The real test will come this Saturday at the next auto-x event where I'm hoping that the extra roll stiffness will help keep the body roll I was experiencing after switching to R-compound tires under control.

Duke Schimmer

'72 2-Door 510

"Simplify and add lightness."

'72 2-Door 510

"Simplify and add lightness."