Page 60 of 63

Re: PoorMtnKids 70 2DR

Posted: 26 May 2014 08:39

by PoorMtnKid

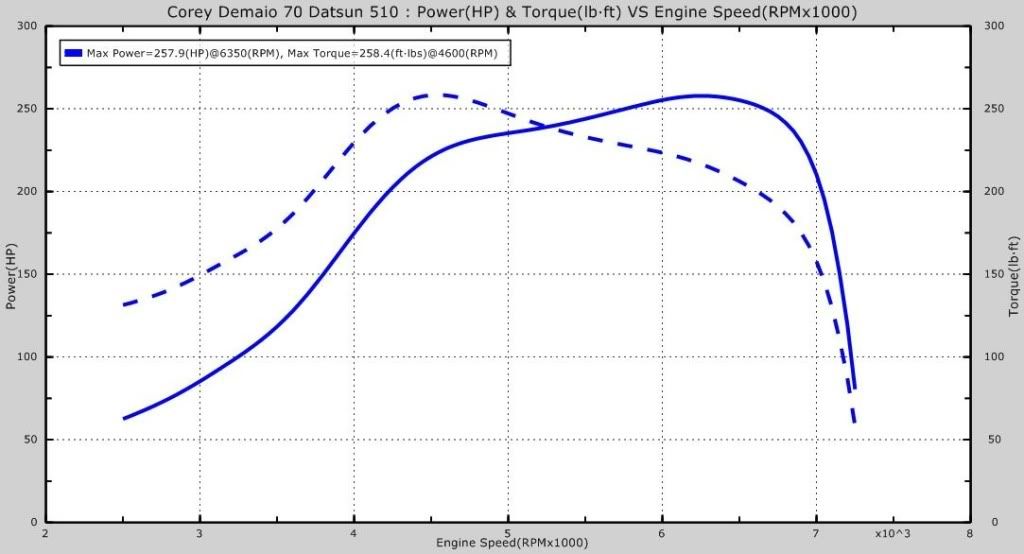

You can see where the HP dies off just after 6k RPM is where the turbo is loosing pressure at that point. 7500 RPM is read line

Re: PoorMtnKids 70 2DR

Posted: 26 May 2014 12:45

by bertvorgon

I will post up a "Compressor Map" when I get home, so you and other can get an idea of what I'm talking about.

Your Hp and torque are virtually like mine, except mine does not fall of quite like that at the top end.

This is due to my larger turbine housing and cam shaft profile, among other things.

Makes for a nice ride in our light cars.

Re: PoorMtnKids 70 2DR

Posted: 26 May 2014 14:34

by TUF510

i would add to do a boost leak test, compression test and leak down test to what the others have said..

Also it would be interesting to see a timing map of your ecu and compare it to other sr20 running same setup

Re: PoorMtnKids 70 2DR

Posted: 26 May 2014 15:22

by dislexicdime

I wouldn't push a t25 that hard in less I was planning on getting a bigger turbo

Re: PoorMtnKids 70 2DR

Posted: 26 May 2014 16:08

by bertvorgon

So, here is a compressor map. This one specifically is from my original 2 liter motor, with a "small" compressor wheel and housing on it. The #168 is the sizing of this compressor.

I'm sure you might be in the zone of where you should be, but, maybe someone who knows your type of turbo can chime in. Rob is a whiz at this stuff.

The left side of the map is the pressure ratio..or BOOST. 2.0 is 2 atmospheres, 14.7 at sea level + 14.7 lbs of boost. The bottom of the map is a calculated CFM flow into the motor. In my case we roughly calculated 285 CFM for mathematical purposes.

Then we calculate what the engine is flowing at a given RPM, you can see the straight lines with the revs marked.

The line ( called SURGE LINE) with the LARGE numbers is the turbine speed, to the LEFT of that is an area of instability, where the compressor cannot pump any more air, and starts to generate lots of heat and can blow back into the compressor wheel. This is sometimes the sound you hear when some NON blow off valved cars lift off the throttle, and you hear the slushing sound.

You can see in the graph area some kinda concentric rings..65...63...62....55... this is the areas of efficiency, as a percentage. At 6,000 RPM, you can see I was only 55% efficient, and at 8,000 RPM, it was useless. Lots of heat would be generated and no increase on pressure. The turbo is spinning at some 90,000 RPM

Then, we plotted an acceleration curve through the map, where, as the boost went up (I run 16 PSI) and peaked, the compressor has fallen off the map, not good. so, this prompted me to get the next size compressor wheel and housing. Now, I run a very much larger setup, heat went down and I am in at least a 75+% area most of the time. Coupled with a larger exhaust 3" and camshaft to match the boost and flow, I only see discharge temps in the 120 - 150F range.

your turbo will have the same sort of map, showing where it flows best.

turbine housings both govern WHEN you want boost built by, and, how much it will boost, given ultimate flow issues.

My turbo is a dinosaur compared to today's stuff, 1960's technology, but, it has a HUGE bearing, and, as I lucked out on a compressor size that works really well, I have not messed with success. It does a job. I do have a larger turbine housing I keep threatening to try, but, have been a bit gun shy as I like how my motor responds right now. I can tell you a story about the BIG housing I put on once...that's for another day.

http://www.turbobygarrett.com/turbobyga ... essor_maps

Re: PoorMtnKids 70 2DR

Posted: 26 May 2014 19:04

by StrutlessWonder

Here's your turbo (I think):

http://www.turbobygarrett.com/turbobyga ... er#GT2554R

And here's your map (snipped from the above page):

Re: PoorMtnKids 70 2DR

Posted: 27 May 2014 07:21

by PoorMtnKid

Alright Bert, you got to help me out here with this graph. So if 'm understanding it correctly based on your explanation of your graph and what Stutless provided, I'm sitting around the 65% efficiency range???

What about the graph on the right?

Re: PoorMtnKids 70 2DR

Posted: 27 May 2014 12:50

by bertvorgon

As we do not know how much air you are sucking in, this is a bit of a guess. But, that being said, depending on what boost you are running, say 12 - 15 psi and moving maybe 250 - 300 cfm, you maybe in that 65 - 68% range on the map. These things become as much a mathematical exercise, as they do to the real world. Others that have run your type of turbo from their real world experience, and sameness of engine, would be the ones to listen to. The comment of not pushing that turbo that hard says something, so to me, you are not in a great efficiency area. Maybe Dislexicdime can chime in. I know for me personally, that the snappiest setup for the street and Solo, was too small for road racing and hillclimb use, where you are wide open for a long time, and spending more time in the upper rpm range.

I would assume your engine is a bit more efficient than mine, in terms of cylinder filling, but, I do have a bigger camshaft and my carb has been modified for way more flow than stock ever was.

A boost number on a gauge is not necessarily what is going into the motor either.

The graph on the right is the pressure for the turbine section. If I read that right, it is starting to flat line for flow in that boost point you maybe at. So, that would say you may need a bigger turbine housing if it is becoming restrictive towards the top end. I know one thing that made a HUGE difference in my setup, was going from a 2.5" to 3" exhaust. If the jump is not too big, that may be worth trying also, without losing a lot of response down lower. It took me about 4 permutations to get mine just right, with the ability to go back down one size on the turbine, should I need ballistic low end boost and response..IE Slalom usage.

Re: PoorMtnKids 70 2DR

Posted: 27 May 2014 17:41

by PoorMtnKid

I do eventually want to upgrade to either a T28 ( stock s14 sr20) or a Garrett GT2871R. The 2871R is from what I read the best turbo the SR responds to before going to a big t3 manifold bolt pattern. The thing I hate is most is people with Sr's are in the drift scene and they are use to the quick sprints and not prolonged abuse. I bet with one of the above mentioned turbos would be able to handle the 14 PSI and be more efficient than the t25 I'm running now.

Re: PoorMtnKids 70 2DR

Posted: 27 May 2014 18:52

by bertvorgon

It sounds like you have a handle on what you need to do. BIG numbers are just that, hell, I could flash 350 RWHP in my car. I have even seen 20 PSI in my car a couple of times...think 10:1 compression ratio with that...Man did it ever accelerate.

I made a decision a long time ago to live within parameters that would actually let me make some incredibly reliable, honest HP...I wanted to drive..not rebuild burnt motors. I have more than once watched BIG number cars melt down trying to keep up with me at the track...again..the stop light Gran Prix is one thing....go play for 30 minutes on the track with your Fancy 350 Hp motor...on PUMP gas,,,KA-BLOOIE. It's all about heat and detonation management.

You keep the oil and water cool, run what boost the fuel and timing can handle and a motor will last a long time. I got 13 years on my full on race schedule motor, and am now into my 12th year on my latest motor permutation, still running 16 PSI and 10:1 ( aviation fuel on the street and hiway ).

good luck!

Re: PoorMtnKids 70 2DR

Posted: 27 May 2014 20:56

by dislexicdime

You should try turning your boost down to 10psi for the next event and see if it heats up. A t28 at10psi will flow as much as your t25 at 15 psi but with less heat. I bet your 370's are maxed out

Re: PoorMtnKids 70 2DR

Posted: 27 May 2014 22:13

by PoorMtnKid

dislexicdime wrote:You should try turning your boost down to 10psi for the next event and see if it heats up. A t28 at10psi will flow as much as your t25 at 15 psi but with less heat. I bet your 370's are maxed out

Would coming down to 10 really throw off the tune that much?

Re: PoorMtnKids 70 2DR

Posted: 27 May 2014 22:29

by dislexicdime

Most the drift tards around here blow up there t25's running them at 15. I know a few people who can't run more then 10 or 12 pounds because they start leaning out. Hurry up and get your wide band on

Re: PoorMtnKids 70 2DR

Posted: 28 May 2014 06:52

by bertvorgon

I'm curious...for these so called modern turbos with ball bearing center sections, yada, yada, HOW are the failing when you say they "blow-up"?

I thought the whole idea of these things was to eliminate these type of issues. I really would like to understand.

I only had ONE failure in my 39 years of using my turbo, and it was not bearing failure, nor FOD damage. For whatever bizarre reason it went out of balance and took out the compressor wheel and housing on the drive home after a day of racing.

I know my turbo has seen the high side of 90,000+ RPM back when I used a very small turbine housing. It also went into surge for years and years, before I got a compressor by-pass valve, and survived all that too.

Re: PoorMtnKids 70 2DR

Posted: 28 May 2014 07:07

by PoorMtnKid

dislexicdime wrote:Most the drift tards around here blow up there t25's running them at 15. I know a few people who can't run more then 10 or 12 pounds because they start leaning out. Hurry up and get your wide band on

The wideband is on and wired just need to plug in the gauge same with boost. Car is on jacks right now because Im getting new rear shocks, they will be here Monday. I will hook up those two gauges and do some test runs when I get the new shocks on.